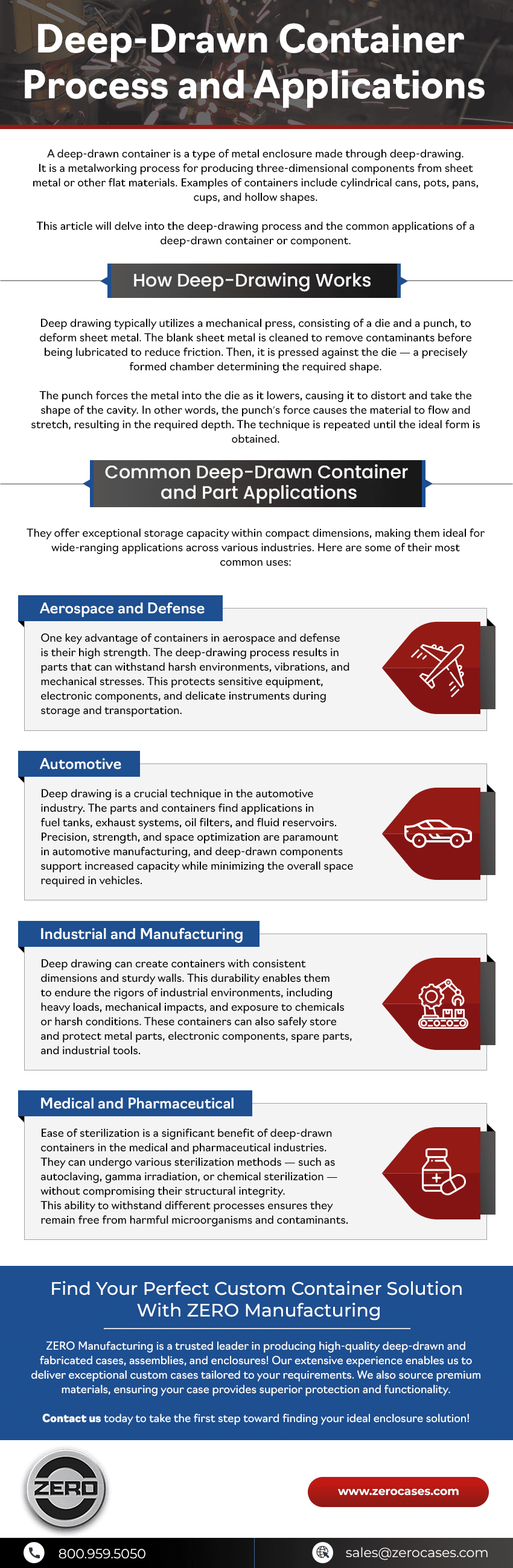

Deep-Drawn Container Process and Applications

A deep-drawn container is a type of metal enclosure made through deep-drawing. It is a metalworking process for producing three-dimensional components from sheet metal or other flat materials. Examples of containers include cylindrical cans, pots, pans, cups, and hollow shapes.

This article will delve into the deep-drawing process and the common applications of a deep-drawn container or component.

How Deep-Drawing Works

Deep drawing typically utilizes a mechanical press, consisting of a die and a punch, to deform sheet metal. The blank sheet metal is cleaned to remove contaminants before being lubricated to reduce friction. Then, it is pressed against the die — a precisely formed chamber determining the required shape.

The punch forces the metal into the die as it lowers, causing it to distort and take the shape of the cavity. In other words, the punch’s force causes the material to flow and stretch, resulting in the required depth. The technique is repeated until the ideal form is obtained.

Common Deep-Drawn Container and Part Applications

They offer exceptional storage capacity within compact dimensions, making them ideal for wide-ranging applications across various industries. Here are some of their most common uses:

Aerospace and Defense

One key advantage of containers in aerospace and defense is their high strength. The deep-drawing process results in parts that can withstand harsh environments, vibrations, and mechanical stresses. This protects sensitive equipment, electronic components, and delicate instruments during storage and transportation.

Automotive

Deep drawing is a crucial technique in the automotive industry. The parts and containers find applications in fuel tanks, exhaust systems, oil filters, and fluid reservoirs. Precision, strength, and space optimization are paramount in automotive manufacturing, and deep-drawn components support increased capacity while minimizing the overall space required in vehicles.

Industrial and Manufacturing

Deep drawing can create containers with consistent dimensions and sturdy walls. This durability enables them to endure the rigors of industrial environments, including heavy loads, mechanical impacts, and exposure to chemicals or harsh conditions. These containers can also safely store and protect metal parts, electronic components, spare parts, and industrial tools.

Medical and Pharmaceutical

Ease of sterilization is a significant benefit of deep-drawn containers in the medical and pharmaceutical industries. They can undergo various sterilization methods — such as autoclaving, gamma irradiation, or chemical sterilization — without compromising their structural integrity. This ability to withstand different processes ensures they remain free from harmful microorganisms and contaminants.

Find Your Perfect Custom Container Solution With ZERO Manufacturing

ZERO Manufacturing is a trusted leader in producing high-quality deep-drawn and fabricated cases, assemblies, and enclosures! Our extensive experience enables us to deliver exceptional custom cases tailored to your requirements. We also source premium materials, ensuring your case provides superior protection and functionality.

Contact us today to take the first step toward finding your ideal enclosure solution!